- E-mail : info_marketing@jindunchemical.cn

- Phone : +86 21 64057580

- Address : Shanghai China

Methacrylic acid monomer is safe and environmentally friendly

Methacrylic acid monomers are an important class of chemical raw materials,

mainly referring to methyl methacrylate extremely derivatives. Methacrylate

monomers impart a variety of properties to products, either to improve strength,

to increase toughness, to provide hydrophilicity, or to provide hydrophobicity,

etc. Methacrylic acid monomers can provide a variety of functional groups with

different properties for polymers, offering a wide range of options and great

imagination for product design.

Methacrylate monomers are very easy to polymerize, so there are certain

requirements for temperature, light, storage containers and storage capacity

during storage, transportation and use, and the addition of polymerization

inhibitors can also have an impact, and some product processes will require

delamination.

Methacrylic acid class part of the monomer applications

Coatings

The addition of different methacrylic acid esters in the synthesis of

resins for coatings can obtain resins with different performance requirements. Methyl methacrylate (MMA) is one of the most used methacrylic monomers. It is a

colorless and transparent liquid at room temperature with a glass transition

temperature Tg of 105°C. It has excellent light transmittance and good

weathering resistance, high hardness, and its addition can significantly improve

the hardness, water resistance and weathering resistance of film-forming

substances. In contrast, the glass transition temperature of n-butyl

methacrylate is only 20℃, which can be used as soft monomer and has obvious

effect on improving the flexibility of resin. Cyclohexyl methacrylate (c-HMA)

can significantly improve the hardness, abrasion resistance and heat resistance

of products under the premise of ensuring weather resistance, and can be used in

high-grade industrial coatings. Isobornyl methacrylate (IBOMA) is often used in

the synthesis of high-grade acrylic resins with high solids and low viscosity

due to its extremely high Tg and unique structure, and this resin has better

heat resistance, weather resistance, wear resistance and water resistance, and

is mostly used in the production of automotive paints. Hydroxyalkyl methacrylate

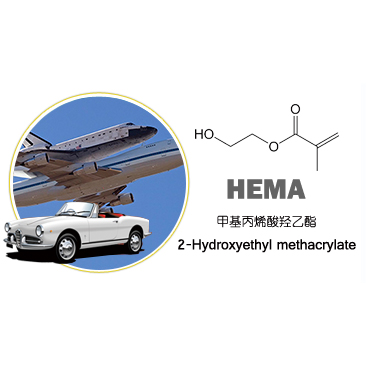

such as hydroxyethyl methacrylate (HEMA) can introduce reactive hydroxyl groups,

which can produce thermosetting acrylic resins, and then cross-link with amino

resins or resins containing polyisocyanates to prepare functional coatings with

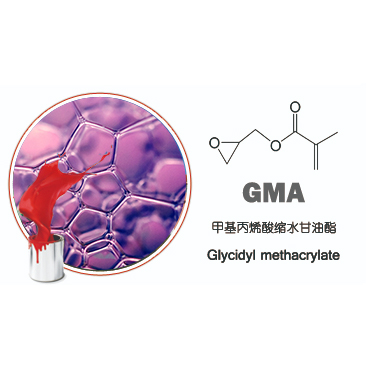

different properties. Glycidyl Methacrylate (GMA) is a monomer that has both an

acrylate double bond and an epoxy group. The acrylate double bond is highly

reactive and can undergo self-polymerization and copolymerization with many

other monomers, while the epoxy group can react with hydroxyl, amino, carboxyl

or anhydride groups to introduce more functional groups and thus bring more

functionality to the product. Therefore, GMA has a wide range of applications in

organic synthesis, polymer synthesis, polymer modification, composite materials,

UV-curable materials, coatings, adhesives, leather, chemical fiber, paper and

printing and dyeing, etc.

Textile

Hydroxyethyl methacrylate (HEMA) is currently used in the grafting process

of silk and other fibers because of its non-toxic and mild odor; the polymer of

dimethylaminoethyl methacrylate (MADAME) can be used as a fiber antistatic

agent, as well as a dyeing modifier for acrylic fibers and polypropylene fibers,

and a treatment agent for polyester, wool, silk, polyurethane fibers and other

fibers.

Medical and Personal Care

Ultra-high purity hydroxyethyl methacrylate (HEMA) is an important material

for making contact lenses; methyl methacrylate (MMA), butyl methacrylate (BMA)

hydroxyethyl methacrylate (HEMA) and other monomers are widely used in dental

materials.

-

date

2022-10-10

-

location

Shanghai, China